Part Description:

Choosing the right lifting joint method directly affects the reliability, safety and service life of the equipment. This program is currently the safest, most economical and adaptable joint solution. It has been adopted by many conveyor equipment manufacturers and has been recognized and praised by many experts.

Description

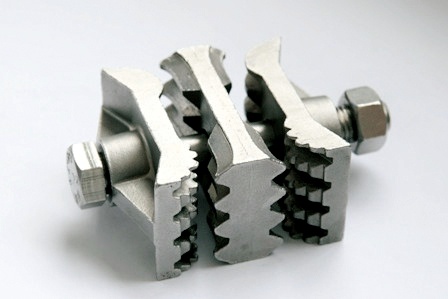

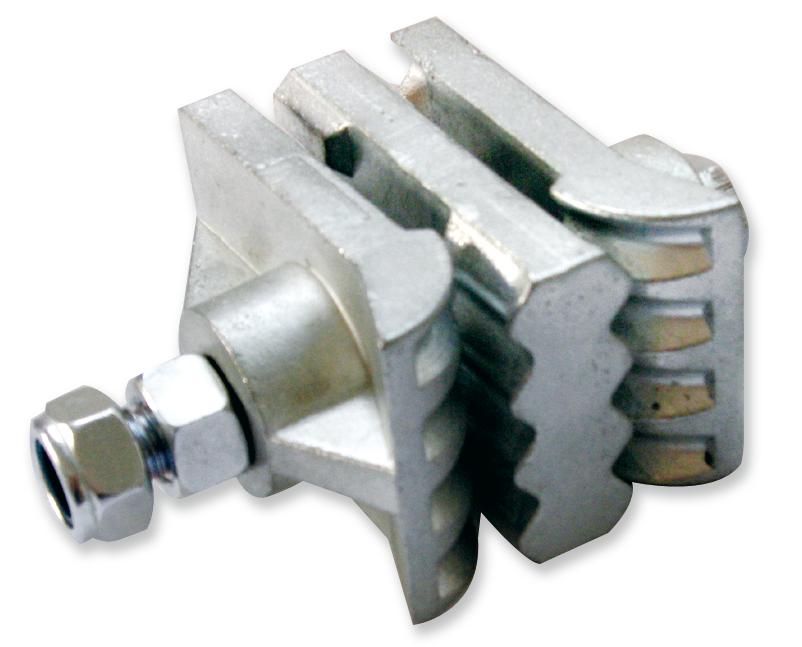

S1.S4.S5 type performance characteristics:

1.S1 type belt connector is integrally stamped and formed, with good dimensional consistency, easy interchangeability and high combination precision;

2.S4, S5 type belt connector is composed of 3 special structures The mechanical connecting parts are made of precision casting, the dimensional consistency is good, the material is cast steel (galvanized) and stainless steel, which has higher clamping force;

3. The belt connector has strong combination ability, which can facilitate the selection of different bandwidths;

4. The belt connector is galvanized and has good anti-rust effect.

5. It is equipped with a lock nut to effectively prevent loosening of the running fastener.

Specification and strength allowable table:

| specification | S1 | S2 | S4 | S5 |

| Allowable tensile strength KN/m | ≤800 | ≤1000 | ≤1200 | ≤1600 |

Belt connector connection form:

Operating points of the belt connector connector:

1, according to different lifting belt tensile strength, lifting belt width to choose different connector models and quantities;

2, the net length of the hoist one week + the length of the joint required for the belt connector = the total length of the required lifting belt; (joint length: S1 + 180mm, S2 + 190mm, S4 + 220mm, S5 + 230mm)

3. Move a certain distance (S1/S2—60mm, S4/S5—80mm) from the two ends of the belt at the joint, and draw a center line of the mounting hole. The center line and the radial direction of the lifting belt must be guaranteed. The two ends of the lifting belt are vertical to ensure that the lifting belt behind the joint does not run off when running.